Introduction

Absorption refrigeration cycle was used before vapor-compression refrigeration became popular, especially in factories for cooling and making ice. When electric compressors came into the picture, vapor-compression systems took over because they could cool more effectively. They also used cheaper refrigerants and were safer.

Nevertheless, absorption refrigeration still has its place in situations when low noise levels is important or when there’s a cheaper energy source available.

The absorption circuit cooling option is emerging as a technical option that increases energy efficiency, especially in hot climates, as the largest share of electricity consumption reaches 60% during the summer to operate air conditioners.

Researchers in this field are trying to balance reducing energy consumption with maintaining levels of thermal comfort. Therefore, there is a constant development in this field to raise efficiency, develop the system, and expand the possibility of using the absorption circuit in the field of air conditioning and cooling more and benefit from the advantages available from it.

Fluids in the absorption cycle

The preference for one of the two options over the other comes from technical considerations. Such as the required operating temperature, as lithium bromide is used in large central applications, while ammonia has the potential to offer very low temperatures suitable for industrial cooling and deep cooling.

As for chemical safety, ammonia is considered a volatile toxic substance, so safety precautions must be taken when handling it. Lithium liquid adsorption systems need constant supervision to prevent salt crystallization.

The principle of working of the absorption circuit

When you add heat to a liquid, its temperature gradually rises until it hits a certain point. Once it exceeds that point, the liquid changes into a gas through evaporation, absorbing heat as it does so. Remove that heat, and the gas turns back into a liquid through condensation.

This principle lets us move heat from the area we want to cool to the outside using a special refrigerant. It’s all part of a cycle that keeps repeating until we reach the temperature we want.

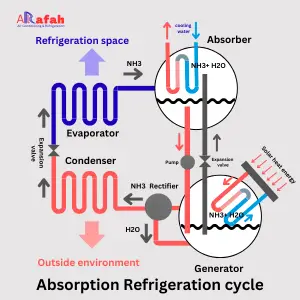

A basic absorption refrigeration cycle has a few key parts: evaporator, absorbent, generator, expansion valve, pump, and refrigerant (usually a mix of water and ammonia or water and lithium bromide).

How absorption refrigeration cycle works using water and ammonia:

- Ammonia at low pressure comes out of the expansion valve and goes into the evaporator.

- The evaporator absorbs heat from the cooling area, making the ammonia turn into a vapor.

- The vapor goes to the absorber.

- In the absorber, the vapor mixes with water.

- The mix gets pumped to the generator.

- The generator uses heat from outside to raise the pressure of the mix.

- Water separates from the ammonia gas and goes back to the absorber.

- The ammonia gas goes to the condenser.

- Heat gets released outside, turning the ammonia into a liquid.

- The liquid ammonia goes through the expansion valve, entering the evaporator at low pressure again.

- The cycle starts over, moving heat from the cooling area to the outside until we reach the right temperature.

Comparing the operation of the absorption cycle with the compression cycle:

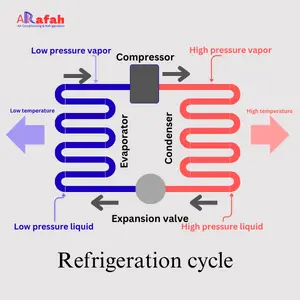

- The absorption cycle relies on thermal, physical, and chemical processes of the refrigerant, while the compression cycle depends on adding energy through the electrical compressor.

- The refrigerant consists of two substances, for example, (water-ammonia) or (water-lithium bromide), while in the compression cycle, there is only one refrigerant.

- The initial cost of an absorption device is high relative to the generated capacity, but the operating cost may be lower if we rely on a cheap or free heat source such as solar energy.

- The absorption cycle system is quieter than the compression cycle due to the absence of moving parts.

- Maintenance costs are lower than the compression cycle because there are no moving parts that can cause mechanical and electrical failures, oil changes, and so on.

- The compression cooling system is small comparing to the absorption refrigerant system at the same capacity.

- From the environment impact point of view the compression system is harmful in case of gas leakage than absorption refrigeration system.

| Comparison Standard | Compression Cooling Circuit | Absorbent Cooling Circuit |

| COP Thermal Efficiency | 3-6 | 0.6-1.2 |

| Electricity Consumption | High | Very low |

| Heat Consumption | Not required | Need a heat source |

| Initial Costs | Less than absorbent circuit | High |

| Operational Costs | High | Low if a free heat source is available |

| Maintenance Costs | By type of loads | By type of loads |

| Order size | Small compared to the same capacity | Large compared to the same capacity |

| Environmental impact | Harmful in case of gas leakage | No harmful gases to the environment |

Maintenance Costs and Requirements

Since there are no complex mechanical components such as compressors and bulky pumps, the maintenance requirements of an absorption cooling circuit are less expensive than that of a compression circuit.

On the other hand, chemical follow-up is needed to maintain the ratio and concentration of fluids in the circuit and check for salt non-formation in the system to avoid clogging of the pipes.

Also, as a result of the possibility of toxic ammonia leakage from the circuit, it is necessary to ensure the seals and seals of the tanks. Periodic cleaning of exchangers should be observed so that sediment does not accumulate on the surfaces of the exchangers resulting in a decrease in their efficiency.

Therefore, if there is a technical team trained in absorption systems, maintenance is easier compared to traditional systems because there are no mechanical failures or change in the charge of the refrigerant medium.

Conclusion

The absorption cooling circuit was used before the compression cooling circuit, but the fact that the absorption circuit is less effective in relation to its size compared to the compression circuit, it was limited to a lower percentage in refrigeration. The compression circuit dominated the refrigeration market widely, especially because of the ease of using electricity more than generating heat.

From the comparison between the adsorbent and compressive systems, the economic feasibility of the absorption system depends on the provision of a cheap or free heat source, such as the waste heat energy from the energy collectors or the possibility of using solar energy in heat generation.

Nowadays with the need to reduce energy consumption and take advantage of wasted energies to raise the efficiency of the energy consumed in industrial or commercial, it became possible to benefit from the absorption circuit in many places. Wherever thermal energy is available Easily and at a low price as secondary energy output or wasted energy.

As an example of using this method for cooling, in small office refrigerators, some air conditioning chillers, and when we can utilize solar heaters.